Selecting the right commercial ice maker is crucial for any foodservice operation. This guide delves into the robust features of a durable stainless steel ice maker, explores its efficient operation and eco-friendly design, and provides a detailed, actionable setup checklist to ensure optimal performance and longevity for your business.

Engineering for Endurance: Stainless Steel and Climate Compatibility

At the core of this unit is its heavy-duty stainless steel construction, a material chosen for its superior durability and corrosion resistance in demanding environments. This aligns with industry standards where stainless steel is preferred for its hygienic properties and ease of cleaning, as noted in discussions on commercial kitchen equipment. The machine’s compatibility with climate types SN, N, and ST signifies its reliable performance across varied ambient temperatures, from subtropical to temperate environments. This broad compatibility, as supported by HVAC principles documented on Wikipedia, ensures consistent ice production whether installed in a humid kitchen or a cooler back-of-house area, making it a versatile asset for restaurants, bars, and hotels.

Efficient Power and Eco-Conscious Refrigeration

Designed for standard 110V/60Hz operation, this ice maker integrates a 780W system using environmentally friendly R290 (propane) refrigerant. R290 is a hydrocarbon with a very low Global Warming Potential (GWP), a topic extensively covered in refrigerant discussions. Its use reflects a growing industry shift towards natural refrigerants due to environmental regulations and efficiency gains. As highlighted in a 2023 Reddit thread on r/refrigeration, technicians note that while R290 systems require careful handling due to flammability, they offer excellent thermodynamic performance and are considered a future-proof choice, contributing to lower operational costs and a reduced carbon footprint for your business.

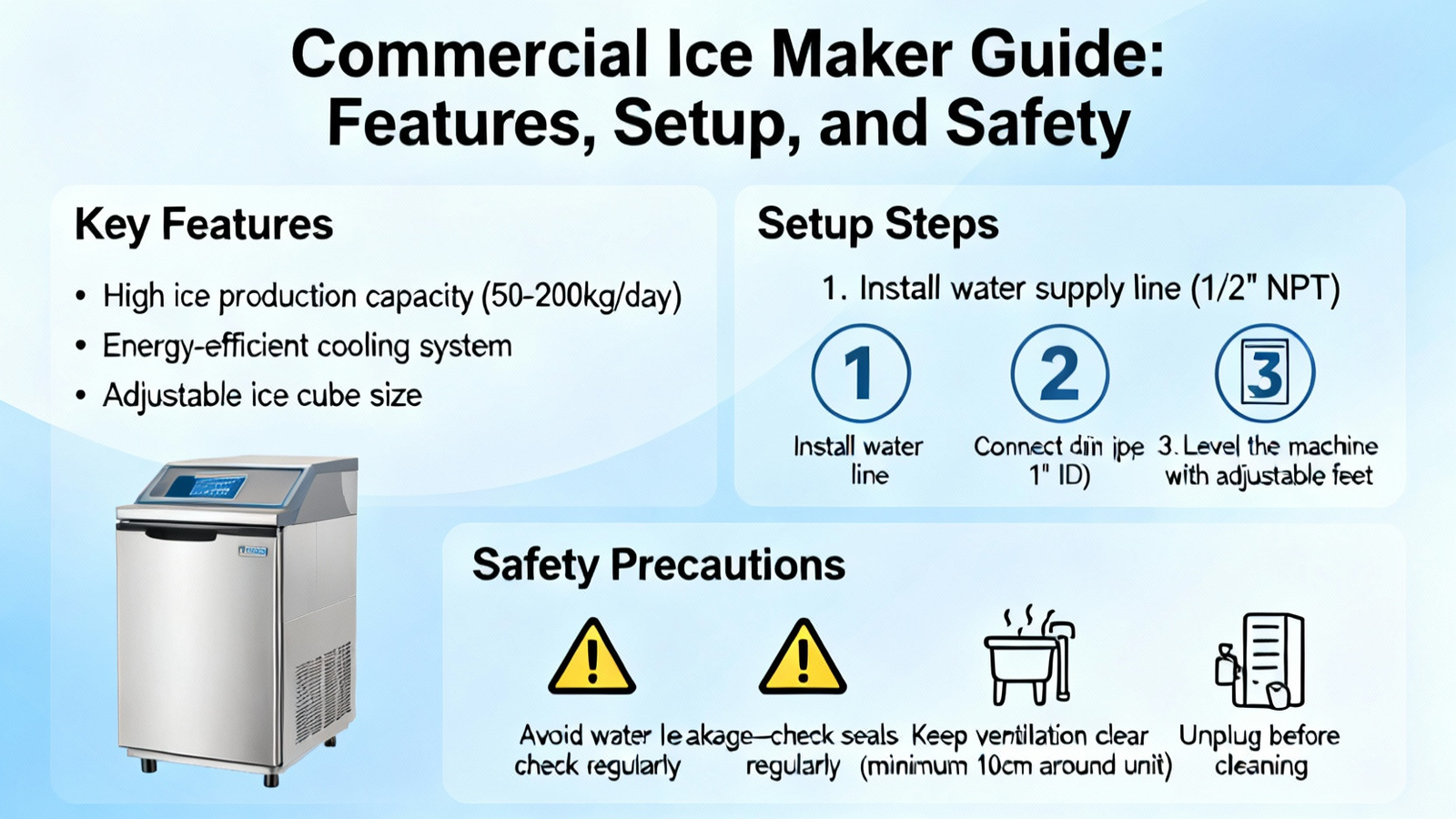

Strategic Installation for Optimal Performance

Proper installation is non-negotiable for safety and efficiency. This model requires a dedicated drinking water supply with precise pressure (14.5-58 psi) and a gravity-fed drain connection, as the unit continuously purges wastewater during its cycle—a common feature in commercial ice makers to ensure ice clarity. Critical spacing of at least 5.9 inches on all sides is mandatory for airflow, preventing compressor overload. Furthermore, the instruction to let the unit stand upright for 24 hours before initial use is vital. This allows the compressor oil, which may have shifted during transit, to settle, preventing severe damage upon startup—a point often emphasized by equipment technicians in online forums.

Essential Safety and Operational Protocols

Adhering to safety guidelines protects both your investment and your premises. The included three-prong plug and 70-inch cord are designed for a dedicated outlet; extension cords are strongly discouraged as they can overheat under the sustained 780W load, creating a fire hazard. The unit must be kept away from heat sources and direct sunlight, as ambient temperature directly impacts freeze cycles and energy consumption. Importantly, only potable water should be used. Using other liquids can damage the system and create unsanitary ice, a fundamental violation of food safety codes. These protocols, combined with the Safety Protection Type I classification, ensure the commercial stainless steel ice maker operates within its engineered safety parameters.

In summary, this heavy-duty commercial ice maker represents a significant investment in reliability and efficiency for any high-volume operation. Its durable stainless steel build ensures longevity, while its R290 refrigerant system positions it as an environmentally conscious choice. However, its advanced engineering demands meticulous attention to installation and safety details—from water pressure and drainage to proper electrical setup and break-in periods. By following the comprehensive guidelines outlined, operators can fully leverage the machine’s capabilities, ensuring a consistent, high-quality ice supply that meets the relentless demands of the hospitality industry. Ultimately, the success of this powerful stainless steel ice maker hinges on integrating its robust design with informed, precise operational practices.